Industrial Joystick & Elements

For Your Unique

Control Solution

We design and manufacture outstanding joysticks for diverse industries.

In Passion. In Innovation. In Motion.

Making Control Stable & Precise

Innovative solutions for the current

And the future

Technologies

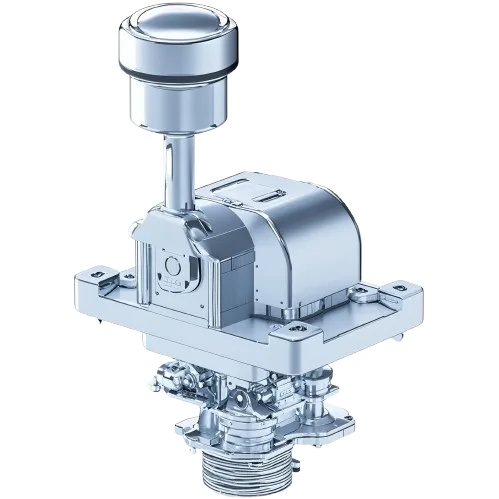

Saekai specializes in manufacturing high-performance industrial joysticks with customizable solutions for diverse applications. Our products feature waterproof, dustproof, shock-resistant, and anti-interference designs to ensure reliable operation in demanding environments.

With our expertise in control technology since 1995, we continue to deliver innovative and robust solutions tailored to your specific needs.

Products

Saekai offers a wide range of high-quality joysticks and control system accessories, crafted from durable materials with innovative designs.

Our products support both potentiometer and encoder configurations, featuring multi-protocol compatibility including CANBUS and PWM to meet demanding industrial requirements.

The product series covers industrial joysticks, fingertip switches, remote controls, control consoles, and limit switches, widely used in marine, aerospace, construction machinery, agricultural equipment, metallurgy, mining, and aerial work platforms.

Industrial Joystick

Suitable for all kinds of heavy machinery, tower crane, lifting equipment

Simulation equipment & control consoles

Fingertip Switch

Often integrated into armrests, simulators & control panels

Remote Control

Commonly used in control systems for overhead cranes & other lifting equipment

Control Console

Commonly used in tower cranes, automation & construction machinery

Integrating multiple control units

Why work with us

Solutions Experts

We recognize that every client has distinct operational demands. From specialized binders to advanced nanocoatings, we deliver customized solutions with innovative technologies to overcome your challenges.

Trusted Partners

For over 30 years we have partnered with our customers, innovating alongside them to create create cutting edge solutions.

Driving Innovation

We pioneer control technology breakthroughs to catalyze technological evolution and develop next-generation solutions for challenges of the future.

Pushing the limits

Our R&D pioneers relentlessly redefine technological boundaries, engineering disruptive innovations that reshape industry paradigms

Process

Good products start with good processes. Here is how we make your products right – through precision engineering, rigorous quality control, and a commitment to excellence at every stage: from design validation to final inspection.

Finalize all technical parameters and designs with customer-approved drawings to ensure specification compliance.

Our vertically integrated facilities (stamping, injection molding, CNC machining) enable complete in-house production of core components for guaranteed quality.

Certified technicians utilize precision tooling systems to achieve micron-level assembly accuracy.

Our in-house trained engineers develop application-optimized solutions with deep domain expertise in product performance.

Every unit undergoes rigorous factory acceptance testing and receives a unique QR code for full lifecycle traceability.

Solutions

Our products serve multi-industries

We pioneer cutting-edge control technologies, transforming industry-specific challenges into tailored solutions. From underground operations to aerospace applications, our precision joysticks and control systems empower industries worldwide.

FAQs

- How frequently is the joystick used?

- What actions should it control?

- How many switch levels does it need?

- Should it be 1, 2, or 3-axis?

These questions will lead you to a right option.

- In order to cope with extreme environments such as extreme cold, extreme heat, dust, humidity, etc., we have customized solutions.

- We use explosion-proof design – deal with explosive environments

- Use DEADMAN design – prevent misoperation

- All our core components are manufactured by ourselves, with a self-sufficiency rate of 95%.

- From raw materials to finished products, we have three inspections: warehouse inspection, patrol inspection, and completion inspection. voluptatibus commodi numquam, error, est. Ea, consequatur.

- Each of our products has a-year-warranty. Place your order without hesitate.

News

ANNIHILATE Failures: 5 SAEKAI Crane Joystick with Lifetime ROI Guarantee

SAEKAI revolutionizes industrial control with crane joysticks engineered to eliminate failures, backed by an unprecedented lifetime ROI guarantee that ensures

SAEKAI’s ROI Calculator: How Our Crane Joysticks Cut Your OpEx by 30%,Might

Discover how SAEKAI’s precision-engineered crane joysticks deliver measurable operational savings. Use our interactive calculator to quantify your potential cost reduction.

Mining & Marine: 4 SAEKAI Crane Joystick Built for Harsh Conditions

Discover the heavy-duty crane joysticks engineered to withstand the world’s most punishing environments. SAEKAI’s specialized controls deliver unmatched reliability where